Specialist for traditional dairy products

From tins, soft packs and glass bottles to pots and single-serving packs, the products have continued to develop with modern packaging formats. Condensed milk is versatile – as a sweetened or unsweetened variant with different fat contents.

From light and creamy to full-bodied

Bärenmarke evaporated milk is highly practical in the resealable bottle.

Find out more

Coffee indulgence with Kaffeeglück

Evaporated milk and coffee cream are ideal for enhancing coffee. Today, Hochwald is the only German producer of tinned evaporated milk, thereby maintaining a longstanding tradition.

Find out more

Evaporated milk for creamy tea indulgence

The Bonny brand has been present on the Arabian Peninsula for more than 50 years. Whether in a tin, glass bottle or single-serving pack, Bonny evaporated milk enhances any tea speciality.

Find out more

Simply versatile

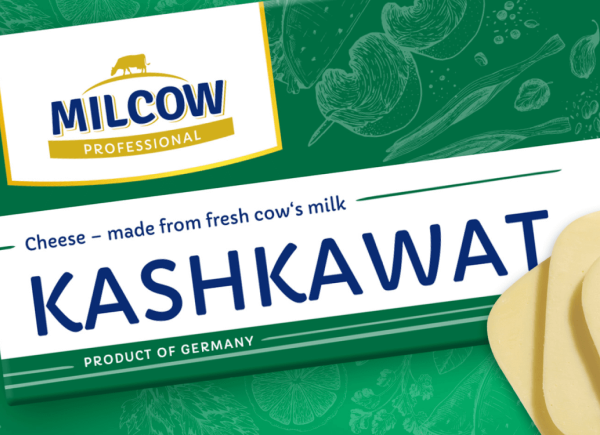

Hochwald has specialised in the production of pasta filata, a scalded cheese that includes mozzarella and kashkaval. We produce for food retail as well as industry. We also offer a range of yellow cheeses with our partners.

Mediterranean indulgence

We regularly supply pasta filata from Germany to the sunny South. That’s because the largest market for this cheese speciality is Italy. Coated in wax and wrapped in film, the cheese stays fresh for longer.

For slicing or grilling

The kashkaval from Hochwald is slightly salted, thereby providing its fine flavour. Available in different sizes.

Making pizza a real pleasure

Quality, browning behaviour, grating and cutting ability are important criteria for mozzarella in further processing. Our customers include many producers of frozen pizzas.

Unique taste

With our brand specialities, we have continuously expanded the yoghurt product range. Whether pure, slightly sweetened, with fruit, firm or stirred.

Greek-style yoghurt

A range of creamy yoghurt – plain or with a variety of fruit. Enjoy the full-bodied taste of Greek-style yoghurt.

Find out more

The firm yoghurt

Northern Germany is home to the firm products of LÜNEbest. Firm yoghurt, whip pudding, chocolate mousse or soured milk.

Find out more

As a fresh or long-life variant

Hochwald milk is produced without genetic engineering. The different shelf lives result from gentle heating processes, which largely retain the natural nutrients.

Regional roots

Kept well chilled, the drinking milk with longer freshness can last for up to 24 days. The long-life milk can keep for six months even without chilling. They are available with different fat contents.

Find out more

makes the difference

The fresh milk has a particularly full-bodied taste. Thanks to gentle pasteurising, the natural freshness is maintained, while the vitamins are almost completely preserved.

Find out more

Drinking milk from Bonny

Long-life drinking milk is exported worldwide. Hochwald has been present in the Arabian market with the Bonny brand since 1968.

Find out more

Highest quality standards

With high-quality ingredients, we are reliable partners of the food industry as well as baby and children’s food sector. We develop the right solution for a wide range of applications.

Always an extra helping of indulgence

Whipped cream, spray cream, sterile cream or sour cream – from fresh in a pot, ready to spray from a can or with a long shelf life in soft packs, Hochwald offers a wide range of fat contents and flavours with different amounts of sugar.

Fresh, creamy taste

Thanks to the fat content of at least 32%, the fresh whipped cream is particularly easy to whip. It tastes great with cake or dessert and can enhance many cooked dishes.

Find out more

Design meets ZEITGEIST

Hochwald has created this vintage inspired brand to meet in particular taste of young consumers. Home cooking and baking, just as in good old times, is now even more fun!

Flavour to go

The milk products combined with coffee, chocolate, vanilla or fruit flavours in a number of varieties offer drinking pleasure at home and on the go.

For all ages and tastes

Hochwald offers a wide range of refreshing milkshakes in large and small packaging. Whether ice chocolate or ice coffee in a range of varieties – there is something for everyone.

Find out more

For the whole family

Little ones will love Bärenmarke cocoa in the fresh and long-life variants. For adults, there is the classic ice coffee as well as new variants latte macchiato and cappuccino.

Find out more

Practical drinking cans

The Bonny brand offers milk drinks and ice coffee in a range of different flavours. From chocolate and fruit to coffee – there is a favourite canned drink for everyone.

Find out more

Hochwald offers an extensive range of services – from developing recipes and packaging formats, to production and logistics. With us, your brand is in good hands. We will be happy to advise you.

At our plants, the milk is processed into high-quality dairy products with lots of experience and competence. This way, we are able to offer a wide range of delicious products for daily consumption and any time of day.